4 Ways Project Managers and Contractors Can Promote Sustainability

Learn The Role You Can Play In Promoting Sustainability As A Construction Project Manager or Contractor

Today, people are finding it more important than ever to “go green”. Green initiatives are being implemented in almost every industry, and construction is no exception.

Contractors and project managers (PM) everywhere are realizing the importance of sustainable choices throughout the building process. However, it’s not always possible for you as a contractor or PM to give your two cents when it comes to green initiatives. That’s when it pays off to be a part of a Design Build project!

In a Design Build, project managers and contractors get to collaborate with architects and engineers before the building begins. This allows the contractor to make changes, give his opinion and make recommendations in regards to best eco-friendly practices.

But what exactly are the benefits of green building, and what are the best ways to promote and maintain sustainability throughout a project? To help you think it through, we’ve compiled a list of four ways to “go green”!

The Value In Green Construction For Project Managers and Contractors

Choosing sustainable options is so much more than “going green”. When contractors push for green options, they are making choices that benefit our environment and economy.

Benefits for the environment

By choosing eco-friendly options, green buildings can benefit our environment by conserving energy and reducing water usage. This can also reduce the amount of toxic or harmful fumes that threaten our environment, like greenhouse gas emissions.

With less power used and less fumes released into the environment, our world would be a different place. Imagine the impact on our environment if every building was made this way!

Benefits for the economy

Green buildings help save money in more ways than one! When tenants aren’t using as much electricity or water, they’ll definitely notice the decrease on their bill. Building owners will have higher resale value due to green materials, too.

Not to mention, sustainable materials are simply more cost effective in the long run. These items are meant to last, and require less to keep them going. While choosing energy efficient options may seem more expensive from the start, the amount owners will save down the road makes it completely worth it!

4 Tips Project Managers and Contractors Can Take With Them Into The Design Build Process To Promote Sustainability

Now that you know the benefits of taking your construction project green, here are four tips to keep your project sustainable:

1. Create A Sustainability Strategy

Before getting started on anything, create a sustainability strategy. First, take a look at your current situation. What are some areas that need improvement? By examining your current processes, you can determine what it will take to improve these areas. This will also help you set and maintain goals for sustainability throughout the project.

Second, once these goals have been identified, assign tasks to specific people who will be held responsible. Just like with any other project, team members have certain jobs to perform. This is no different! Assign project members tasks to promote and maintain eco-friendliness. When everyone has their own responsibility, it will be much easy to stay sustainable!

2. Set Sustainability Standards on Site

Once work has begun, it’s important for contractors to do all they can to remain sustainable on site. There are quite a few ways for this to be achieved:

LED lighting. While this may seem more expensive at first, it will definitely pay off in the end! Not to mention, LED bulbs and lighting options will last significantly longer than regular bulbs. Because of this, they’ll be able to make it through multiple projects, all while maintaining efficiency and keeping costs down.

Proper waste management and recycling. This is a major part of keeping things green. As the project manager, you have multiple ways to influence good habits when it comes to trash and recycling. Keep an eye on items that could be repurposed or recycled, rather than just hauled off to a landfill. Encourage members of your team to properly dispose of items that can’t be reused, and to recycle all items that can!

Monitor runoff. Set up retention ponds around the site to prevent debris from making it into community water areas or freshwater sources. That way you’re keeping the site clean and keeping things eco-friendly!

3. Opt for Green Materials

One of the best parts of being involved in a Design Build is that you get to give your input at the beginning! This is especially helpful when it comes to ordering materials. You have the power and opportunity to recommend ordering materials that are sustainable and friendly to the environment.

Also, you can make recommendations to other key members of the team about green options. Some things to consider are:

Energy-efficient electrical. Make recommendations to the electrical engineers about choosing more energy-efficient options. This could be solar paneling, appliances, wiring, or even making the suggestion to add more windows! This will bring in more natural light and alleviate the need for lights to be kept on all day (and cut costs on energy bills).

Green HVAC. Having an energy-efficient HVAC is key to sustainability! By recommending a green HVAC, you can help owners save big in the future.

Non-toxic paint and finishes. Some cheaper paints and finishes emit high volatile organic compounds (VOCs). These not only threaten the health of the team, but also the health of the tenant. Suggest paints and finishes will lower levels of toxicity that aren’t detrimental to overall well-being, and that promote sustainability.

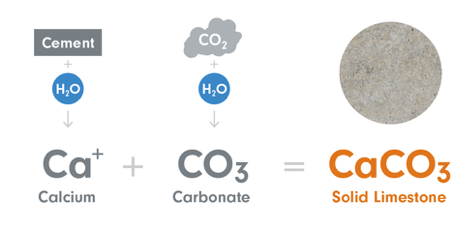

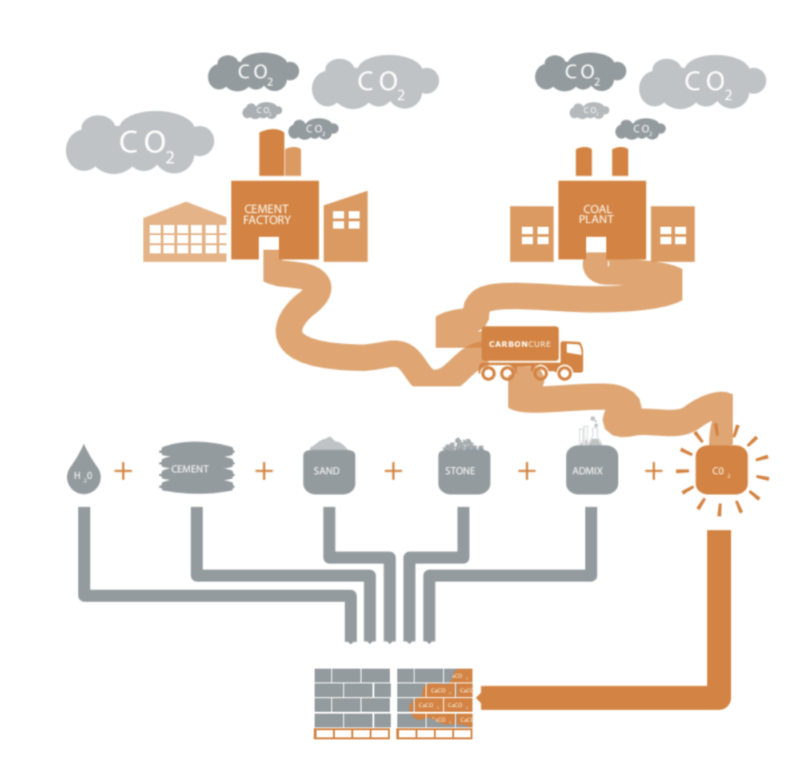

CarbonCure Technology. Carbon Cure’s CO2 utilization technology injects a precise dosage of carbon dioxide into ready-mix concrete masonry products, where it chemically converts into a mineral. Read more about this innovative technology and how it’s promoting sustainability.

4. Choose Reliable Partners

Align yourself with partners who care about sustainability as much as you do! Some partners and suppliers may try to cut costs, therefore nixing your green goals.

While convincing partners to go green is easier said than done, it can be a great opportunity to shed some light on the benefits of choosing sustainable options. If everyone involved in the project understands the value of green initiatives, they will be more willing to put these efforts into action.

However, we know picking the right supplier is no easy task! With so many to choose from, it’s hard to make sure your priorities and goals about sustainability align.

When you’re looking for a concrete supplier who cares about sustainability just as much as you do, look no further than Concrete Supply Co.

At Concrete Supply Co., we are committed to preserving natural resources to not only grow our business, but also protect our environment. We frequently audit our sites to make sure we are conserving our resources through recycling. Not to mention, we are the first ready-mix company in the Carolinas to have earned the National Ready Mixed Concrete Associations Green Star Environmental Certification.

We take pride in our efforts to create a more sustainable, green and eco-friendly environment throughout our projects. Ready to partner up? Contact us to let us know a little bit more about your project and how we can work together!

Looking for a supplier but not sure who to choose? Download our Guide to Pre-Qualifying Suppliers below to help you pick the right suppliers for you!