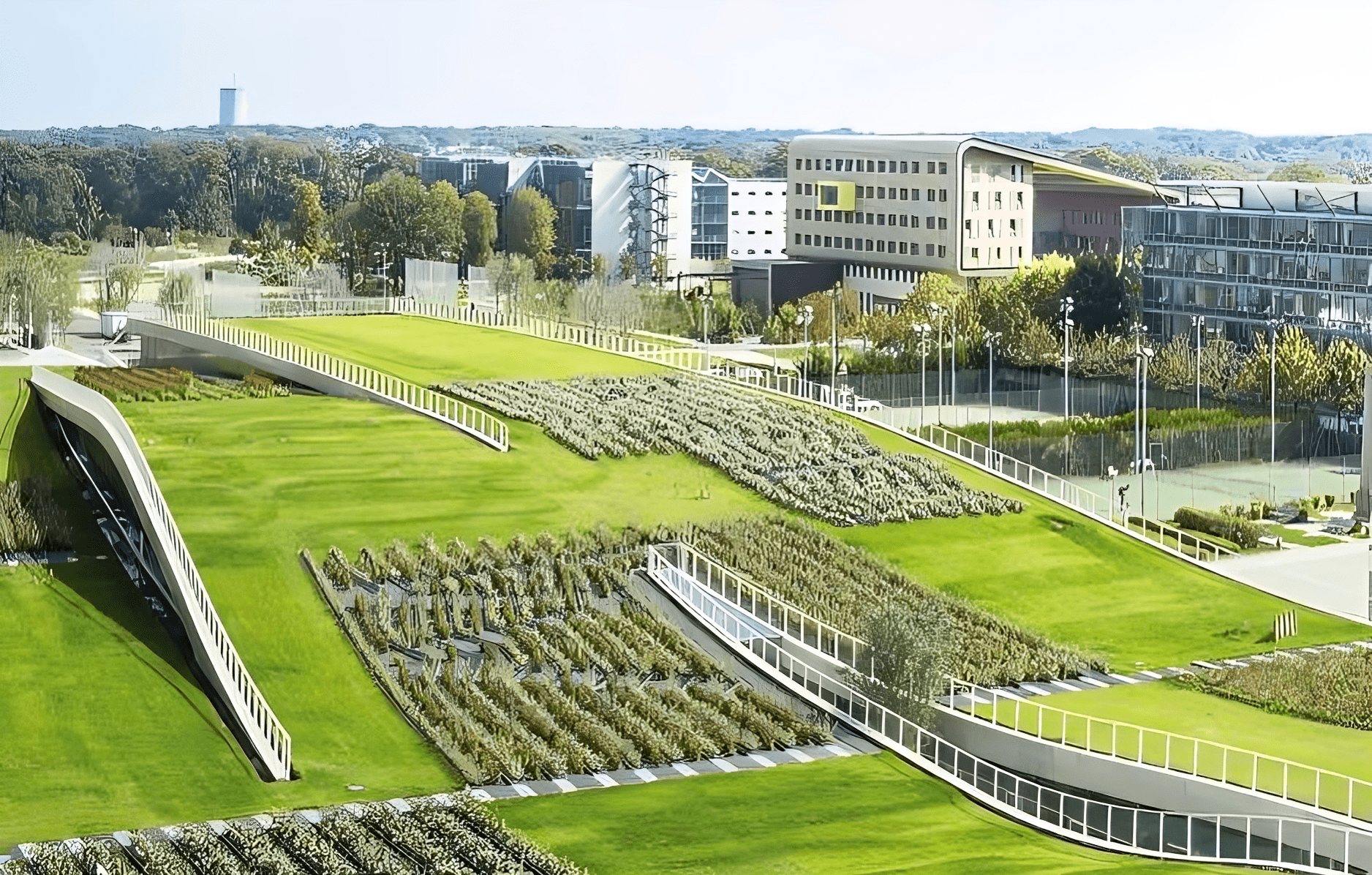

SUSTAINABILITY

Reducing Our Footprint

with Every Project

OUR commitment

Concrete Supply Co., LLC is committed to protecting the environment through sensible and responsible operating activities. We realize that by doing so not only conserves the natural resources that are necessary for our business, but also provides a healthier environment for us all.

To help us accomplish this goal we are committed to minimizing our impact on the environment while increasing our ability to conserve natural resources through recycling. Measuring, monitoring, and constantly improving our sites through the use of regular audits will accomplish this. We will ensure that our sites are operating within compliance of ALL Local, State, Federal, and Concrete Supply Co., LLC’s requirements and standards.

GREEN-STAR CERTIFIED

National Ready Mixed Concrete Associations Green-Star Environmental Certification as well as being one of the first in the country to do so.

The cornerstone of the Green-Star program is the Environmental Management System also known as an EMS. An EMS is part of the overall management system that includes organizational structure, planning activities, responsibilities, practices, procedures, processes and resources for developing, implementing, achieving, reviewing and maintaining environmental policy.

Concrete with recycled CO₂

The CarbonCure technology introduces carbon dioxide (CO₂) into fresh concrete in order to optimize the manufacturing process and reduce its carbon footprint. Once introduced to the concrete mix, the CO₂ chemically converts into a mineral and becomes permanently embedded in the concrete. The process improves the concrete’s strength, which enables us to reduce the cement content in our mixes, further reducing our embodied carbon footprint. On average, every cubic yard of concrete we produce with CarbonCure removes 25 pounds of CO₂ emissions from entering the atmosphere.

The use of the CarbonCure Technology has no impact on the fresh or hardened properties of ready mix concrete, including durability, finishing, workability, pump-ability, temperature, pH or appearance; and it will not impact the construction schedule.

Locations with CarbonCure:

ARE YOU READY TO START YOUR PROJECT?

Reach out today for a quote or with general questions. Our industry experts are standing by ready to assist with your project needs.