How CarbonCure Technology Is Taking The Concrete Industry From Gray To Green

The Impact CarbonCure Technology is Having on the Concrete Industry

Seven percent of the world’s carbon dioxide (CO2) emissions come from cement production. One US Government agency revealed that global cement production was responsible for about four billion pounds of CO2 emissions last year alone.

Cement is the primary–and most widely used–ingredient in concrete. As a result, these emissions are often blamed on the concrete industry.

The government endorsing environmental stewardship programs encourages architects and designers to reduce both the operational and embedded footprint of buildings. While this is a great step towards change, there’s still more that can be done! There are options for designers and architects that don’t just benefit the environment but the structure itself too.

During a United Nations summit on Climate Change in 2007, Rob Niven saw a global need for less carbon emissions.

Rob Niven said, “The scientific community understands that CO2 can be chemically converted to a mineral within concrete. So why can’t we find a way to use CO2 in every-day concrete and help concrete producers respond to the demand for green building products?”

That same year, Rob Niven founded CarbonCure with a goal of reducing the carbon footprint of the concrete industry.

Today, CarbonCure is at the forefront of a movement to turn carbon dioxide into a valuable commodity–concrete!

The progress CarbonCure has made over the last ten years will change the concrete industry as we know it. We like to say, CarbonCure is taking the industry from gray to green–not literally, but definitely for the better!

How CarbonCure Recycles Co2 to Make Better Concrete

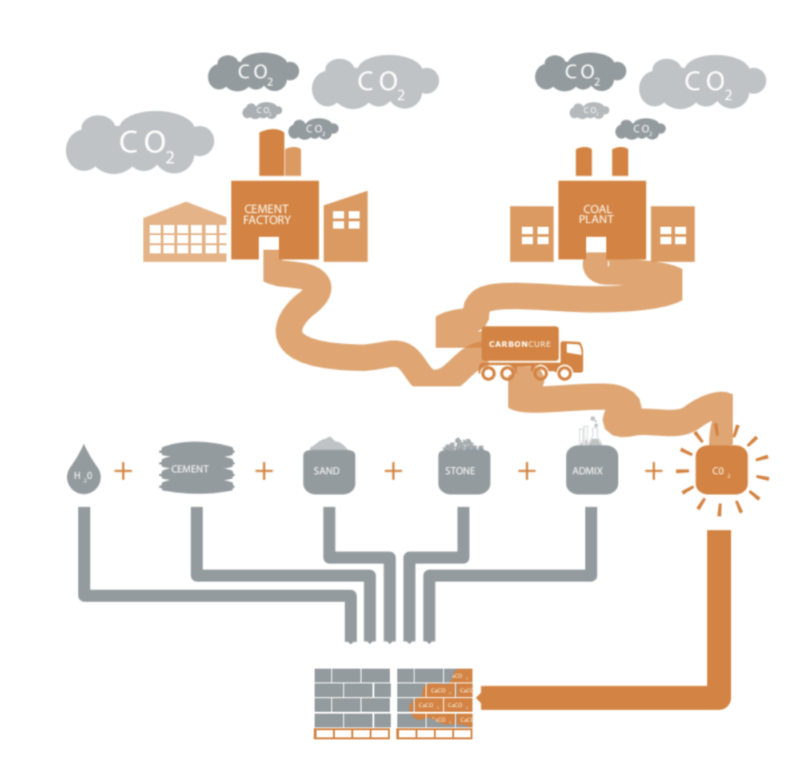

CO2 utilization is an innovative process in which industrial CO2 is captured and used to manufacture valuable products. CarbonCure is the only commercial CO2-utilisation technology currently serving the concrete sector.

CarbonCure’s CO2 utilization technology injects a precise dosage of carbon dioxide (generally between 1-5 fl oz/cwt is recommended) into ready-mix concrete and concrete masonry products, where it chemically converts into a mineral.

The use of CO2 in concrete shows no effect on the mix’s fresh properties–set-time, slump, workability, pump-ability, air content, temperature, and finishing. Or on the hardening properties of the mix–pH, freeze-that, density, color, texture, and durability.

Sourcing CO2

Sourcing CO2 is not the hard part. Third party gas suppliers collect CO2 from industrial emitters then purify, liquefy, and distribute it.

Ready-mix producers are able to store CO2 necessary for production at their plant in a refrigerated, pressurized tank which is refilled regularly by the gas supplier. When discharged, the CO2 is a mixture of gas and a solid white powder.

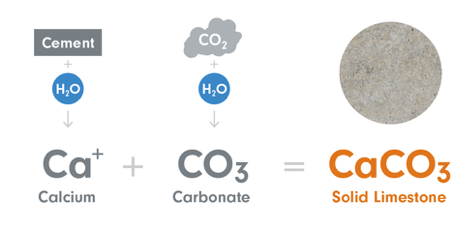

The Reaction

When CO2 is injected into a ready-mix, it reacts with calcium ions in the cement. Eventually this forms a nano-sized calcium carbonate mineral that becomes permanently embedded in the concrete.

This answers most people’s biggest question about CarbonCure: “Will the CO2 ever escape?” Once the CO2 is converted into a mineral, it cannot escape because it no longer exists.

This permanence is a huge sustainability advantage for CarbonCure technology. With almost all other applications, CO2 makes its way back into the atmosphere. CarbonCure will never be released into the atmosphere as a greenhouse gas.

As we said, the concrete industry’s future just went from gray to green!

See the reaction explained in the diagram below.

The Green Future With CarbonCure

The CarbonCure vision is to “make the introduction of CO2 into concrete standard for all concrete production across the globe”.

A world in which CO2 is sourced from cement plants and used by concrete producers to create stronger and greener concrete is now the biggest goal.

The beneficial reuse of CO2 industry is expected to become a $1 trillion industry by the year 2030 according to The Global CO Initiative (GCI).

CO2 utilization products for the concrete sector alone have the potential to reduce up to 1.4 gigatonnes of annual CO2 emissions by 2031. A greener concrete industry is possible.

Concrete Supply Co. is onboard with the change CarbonCure is helping the concrete industry achieve, now what about you? CarbonCure provides FAQ pages to answer all of your questions–whether you are a contractor, engineer, or designer.

Is being eco-friendly a concern of yours when ordering a ready-mix from your supplier? Check sustainability on our Concrete Checklist: Get The Best Ready-mix For Your Project, and plan to use CarbonCure technology with your next mix.